Understanding Heat Treatment and RUSS in Milk Powder Production

The Science Behind Protein Quality in Dairy Ingredients

1. Introduction

Milk powder production may appear simple — just drying milk — but in reality, every stage of processing determines the functionality, solubility, and nutritional quality of the final product. Two key parameters define this quality: the degree of heat treatment and the RUSS (Reference Undenatured Serum Solids) value.

These factors distinguish Low Heat, Medium Heat, and High Heat milk powders — categories that influence everything from infant formula quality to bakery performance.

2. The Role of Heat in Milk Powder Processing

During spray drying, milk is exposed to controlled heat to remove water. This process, while necessary for drying, also affects the whey proteins within milk.

-

Low Heat (LH): minimal heating to preserve protein structure

-

Medium Heat (MH): moderate heating to balance solubility and stability

-

High Heat (HH): strong heating for improved functionality in processed foods

Each type serves a different industrial purpose.

| Type | Preheat Temperature | Protein Denaturation | Typical Application |

|---|---|---|---|

| Low Heat | <70°C | <10% | Infant formula, recombined milk, beverages |

| Medium Heat | 70–90°C | 10–60% | Chocolate, ice cream, general food uses |

| High Heat | >90°C | >70% | Bakery, confectionery, yogurt, processed cheese |

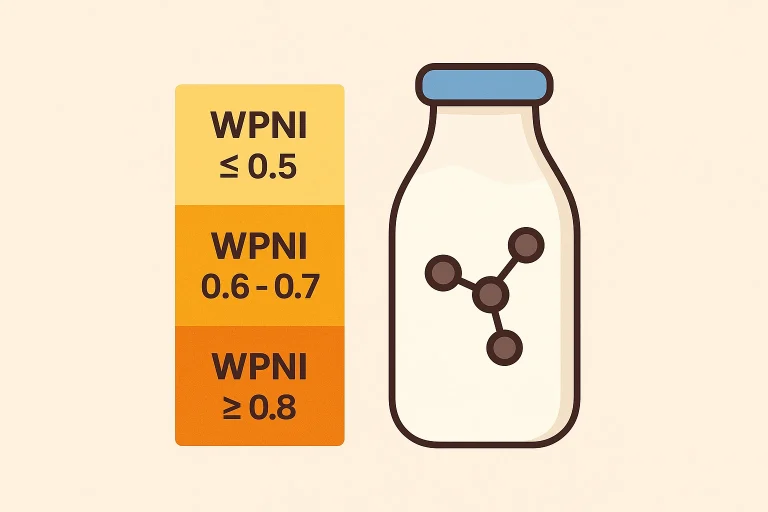

3. What Is RUSS and Why It Matters

RUSS (Reference Undenatured Serum Solids) is a laboratory indicator used to measure how much of the milk’s serum proteins (mainly whey proteins) remain undenatured after heat treatment.

-

High RUSS = Proteins are well-preserved → Low Heat product

-

Low RUSS = Proteins are denatured → High Heat product

Approximate guide:

| Milk Powder Type | RUSS (mg/g) | Heat Classification | Protein Solubility |

|---|---|---|---|

| >6.0 | Low Heat | Excellent | |

| 1.5–6.0 | Medium Heat | Good | |

| <1.5 | High Heat | Moderate–Low |

This means RUSS is a scientific fingerprint of how gently (or strongly) the milk was processed.

4. How Heat and RUSS Affect Milk Powder Functionality

The heat level and RUSS value directly influence how milk powder behaves in different applications:

-

Low Heat / High RUSS:

-

Best solubility and flavor

-

Ideal for recombined liquid milk, infant formula, and nutrition products

-

Retains most of the bioactive proteins (like lactoferrin, α-lactalbumin)

-

-

Medium Heat:

-

Balanced solubility and functionality

-

Common in chocolates, desserts, and ice cream

-

Offers mild heat stability with moderate flavor development

-

-

High Heat / Low RUSS:

-

Less soluble, but highly heat-stable and functional

-

Used in bakery mixes, yogurt, and cheese manufacture

-

Creates better texture and water-binding capacity

-

So, the “best” milk powder depends not on being Low or High Heat — but on matching the powder’s characteristics to the final product requirements.

5. Identifying Heat Class in Milk Powder

Producers usually list the heat class on the technical data sheet (TDS) or certificate of analysis (COA). When it’s not stated, you can estimate it from:

-

RUSS value

-

Solubility index

-

Casein/whey protein ratio

-

Preheat and pasteurization description

For instance, if a milk powder shows RUSS > 6.0 mg/g and very high solubility, it’s almost certainly a Low Heat Skim Milk Powder (LH SMP).

6. Why This Matters for Product Development

Understanding heat classification helps both manufacturers and buyers choose the correct powder:

-

A coffee creamer producer may prefer Medium Heat milk powder for better emulsification.

-

A bakery manufacturer might need High Heat milk powder for improved dough strength.

-

A nutrition company values Low Heat milk powder for its preserved proteins and flavor.

This scientific awareness ensures consistent quality, stable performance, and cost efficiency across applications.

7. Conclusion

The relationship between heat treatment and RUSS defines the core quality attributes of milk powder.

-

Low Heat (High RUSS): high solubility, nutritional value

-

High Heat (Low RUSS): strong functionality and texture

-

Medium Heat: a balanced compromise

By understanding these indicators, companies like Tejarat Chavosh Aryan can design milk powders precisely tailored to the needs of food, beverage, and nutrition industries — ensuring both technical performance and consumer satisfaction.