The Importance of Proper Storage and Temperature Control for Dairy Powders

In the global dairy industry, powdered products such as milk powder, whey protein, and buttermilk powder play a vital role in food manufacturing, nutrition, and export. However, the quality and safety of these powders depend greatly on how they are stored. Proper storage and temperature control are not just operational details they are essential to preserve the product’s flavor, functionality, and nutritional integrity. Companies like Shahdoosh place high importance on maintaining the right environmental conditions to ensure that every batch meets international quality standards.

Understanding the Nature of Dairy Powders

Dairy powders are hygroscopic, meaning they easily absorb moisture from the surrounding air. When exposed to high humidity or fluctuating temperatures, they can develop clumping, off-flavors, and even microbial growth. Therefore, maintaining a stable and controlled environment is crucial to keep the powder free-flowing, clean, and safe for consumption.

The Ideal Storage Conditions

The standard recommendation for most dairy powders, including skim milk powder and whey protein concentrate, is to store them in a cool, dry place between 20–25°C with a relative humidity below 65%. The area should be free from direct sunlight and strong odors, as powders can absorb external smells. Additionally, storage rooms should be well-ventilated and protected from temperature fluctuations, which can lead to condensation inside the packaging.

Temperature Control: A Key Factor for Longevity

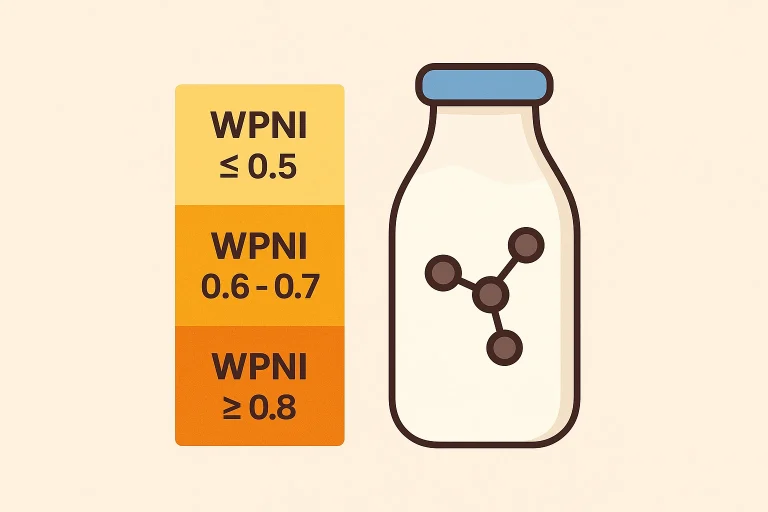

Temperature plays a direct role in the chemical stability of dairy powders. Higher temperatures can accelerate the Maillard reaction (a process where proteins react with lactose), leading to discoloration, nutrient loss, and reduced solubility. Keeping the powder within the optimal temperature range helps maintain protein integrity, flavor stability, and functional performance all of which are essential for industries producing baby formulas, bakery products, or sports nutrition supplements.

The Role of Packaging in Quality Preservation

Even with perfect temperature control, the right packaging is equally important. Dairy powders should be packed in moisture-proof, oxygen-barrier materials such as multilayer bags with inner liners. Vacuum-sealed or nitrogen-flushed packaging helps prevent oxidation and microbial contamination. Shahdoosh utilizes advanced packaging technologies that extend the shelf life of dairy powders without compromising their natural qualities.

Storage Practices for Industrial and Export Settings

For large-scale storage or export operations, warehouses must maintain consistent conditions across all sections. This includes monitoring humidity with sensors, implementing temperature alarms, and scheduling regular inspections. In hot or tropical climates, air conditioning or dehumidifying systems are often necessary. Proper rotation of stock based on the First-In, First-Out (FIFO) principle also ensures that older batches are used before newer ones, preventing waste and quality degradation.

Consequences of Improper Storage

Inadequate temperature control can lead to serious quality issues. Exposure to moisture or heat can cause the powder to harden, develop unpleasant odors, or lose its solubility. Nutritional degradation especially the loss of vitamins like A and D – can occur, along with a decline in overall sensory quality. From an industrial standpoint, these issues not only affect product performance but also cause financial losses and damage to brand reputation.

Sustainable and Smart Storage Solutions

As technology advances, smart monitoring systems now allow real-time tracking of temperature and humidity levels. These systems, combined with energy-efficient refrigeration and optimized logistics, contribute to a more sustainable approach in dairy storage. Shahdoosh integrates modern environmental management strategies to ensure both product safety and eco-friendly operations, aligning with international sustainability standards.

Conclusion

Proper storage and temperature control are fundamental to preserving the integrity of dairy powders. Whether it’s milk powder, whey protein, or buttermilk powder, maintaining optimal environmental conditions ensures long shelf life, consistent quality, and consumer satisfaction. For leading producers like Shahdoosh, excellence in storage management is not just a technical requirement it’s a promise of reliability, safety, and superior taste in every product delivered worldwide.